Because cemented carbide is very valuable, it is the responsibility of every machining practitioner to use the drill correctly and make the best use of everything. The correct use of cemented carbide bits mainly includes the following aspects:

1. Select the correct machine tool. The cemented carbide bit can be applied to CNC machine tools, machining centers and other machine tools with high power and good rigidity, and the tool tip runout TIR < 0.02. However, due to the low power and poor spindle accuracy of rocker drill, milling and other machine tools, it is easy to lead to the early collapse of cemented carbide bit, which should be avoided as far as possible.

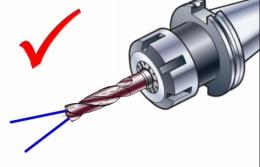

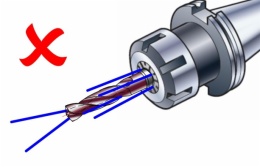

2. Select the correct tool holder, spring collet, side pressing tool holder, hydraulic tool holder, heat rising tool holder, etc. they can be used. However, due to the insufficient clamping force of the quick change drill collet, it is easy to cause the drill bit to slip and fail, so they should not be used.

3. Correct cooling

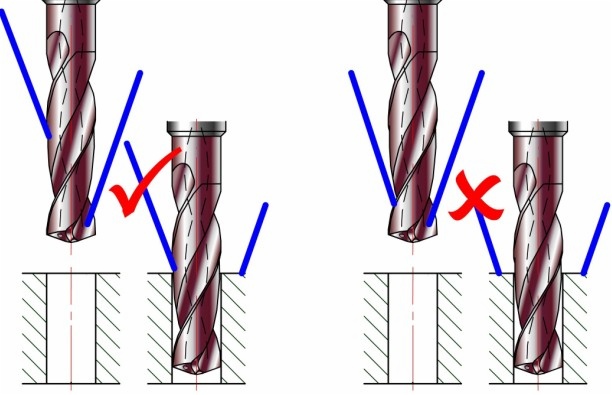

(1) For external cooling, pay attention to the combination of cooling directions, form an upper and lower echelon configuration, and reduce the included angle with the tool as much as possible.

(2)内冷钻头应注意压力和流量,并应防止冷却液泄露影 响冷却效果。

4. Correct drilling technology

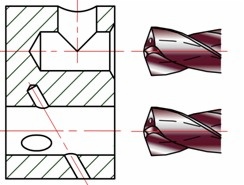

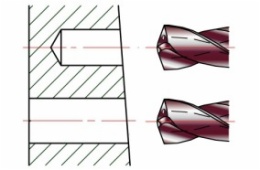

(1) When the dip angle of the drilling surface is > 8-10 °, it cannot be drilled< At 8-10 °, the feed shall be reduced to 1 / 2-1 / 3 of normal;

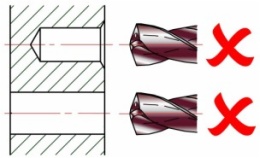

(2) When the dip angle of the exit surface is > 5 °, the feed shall be reduced to 1 / 2-1 / 3 of the normal;

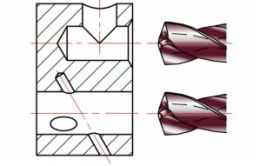

(3) When drilling cross holes (orthogonal holes or oblique holes), the feed shall be reduced to 1 / 2-1 / 3 of the normal;